Displacement Diesel Engine Posted in: AR200 Laser Measurement Sensor – Tags: Displacement Measurement

Last Updated: March 20, 2023

Large diesel-powered generators combine inductors with diesel engines to produce thousands of kilowatts of power. These enormous pieces of capital equipment see extensive preventative maintenance and testing so they reliably and efficiently operate in the field.

The leading electric motor and generator servicing company in the US uses four laser measurement sensors to measure the amplitude of vibration of large diesel generators. Their test setup has the sensors measuring the displacement of the diesel engine (generator) support rails while the system is idling and during heavy loading.

The test instrumentation include the following:

- Zonic Medallion Eigh- Channel Digital Signal Processor

- 4- Acuity laser sensors

- 4 – PCB/IMI 1 volt / g accelerometers

All data was recorded to a computer hard drive at a 5kHz real time rate. This allows for play back utilizing different settings to maximize data interpretation. The Acuity laser measurement sensor can be set to scan over a 0.5” total displacement with as little as a 3 micron resolution. The PCB/IMI accelerometers have a 1 volt/g output from 1 to 5000 Hz.

The readings were recorded while the diesel was running at no load, then full load was applied for approximately 10 seconds and then brought back to no load. Load range was from approximately 100 kw to 2200 kw.

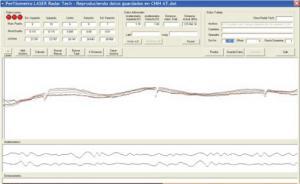

The traces are as follows:

- Top trace (red) – Front Left (diesel) – laser pointed up

- 2nd trace (blue) – Back Left (generator) – laser pointed down

- 3rd trach (Aqua) – Front Right (diesel) – laser pointed up

- Bottom trace (violet) – Back Right (generator) – laser pointed down

The amplitude scale is in inches. The individual trace positions are only relative in this example of displacement measurement. They were set to be approximately mid span for the laser, which is capable of seeing a 0.5” total movement. The traces illustrate that the diesel end of the skid has transitional vibration as the load is applied and removed, but the static position remains the same. However, the traces on the generator end of the skid indicate the right leg raises approximately 0.010” to 0.020” and the left leg moves down the same amount. This considers the static motion as well as the dynamic on top of it.

The amplitude scale is in inches. The individual trace positions are only relative in this example of displacement measurement. They were set to be approximately mid span for the laser, which is capable of seeing a 0.5” total movement. The traces illustrate that the diesel end of the skid has transitional vibration as the load is applied and removed, but the static position remains the same. However, the traces on the generator end of the skid indicate the right leg raises approximately 0.010” to 0.020” and the left leg moves down the same amount. This considers the static motion as well as the dynamic on top of it.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.