Engine Vibration Measurement Posted in: Runout-Vibration – Tags: AR100, AR200, Automotive

Last Updated: March 20, 2023

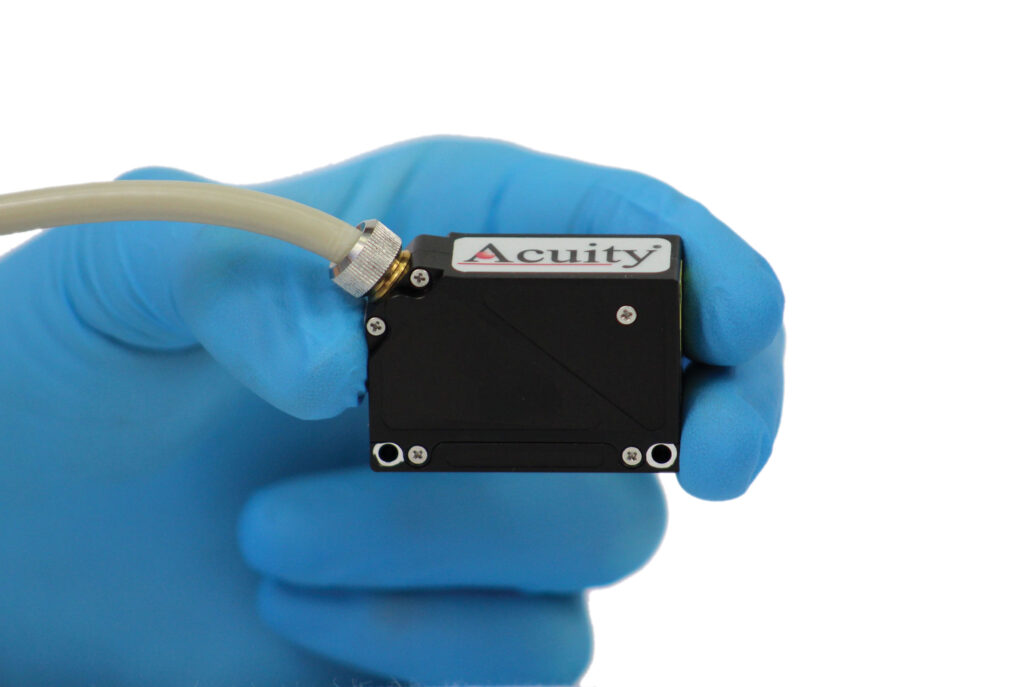

Laser Measurement Sensors for Engine Vibration Measurement

Acuity’s AR100 and AR200 compact laser triangulation sensors are commonly used to monitor and calculate the vibration created by an engine in testing labs. Our cost effective sensors are placed at various sections of the engine to measure the vibration displacement in multiple engine locations.

Laser measurement of engine vibration is preferred over other types of measurement because it is completely non-contact. That allows you to install the sensors away from the engine. Devices such as accelerometers need to be attached to the vibrating parts, and that extra mass affects the vibration measurement, making data less accurate. Acuity lasers are extremely precise, and they can give you the accuracy you need without affecting the results.

Acuity’s AR100 is a common sensor used for this application because of its fast, 9.4kHz sampling rate, compact size, and precision at a cost-effective price.

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.