Why Laser Sensors are Recommended for Steel Manufacturing Posted in: AS2100 Accurate Distance Sensor – Tags: AS2100

Last Updated: March 20, 2023

The steel manufacturing industry is vast with many different functions. Metal and steel production began as a means to produce small and more expensive items like knives, swords and armor. Today, steel is a much larger industry and often needs to look at steelmaking process improvements.

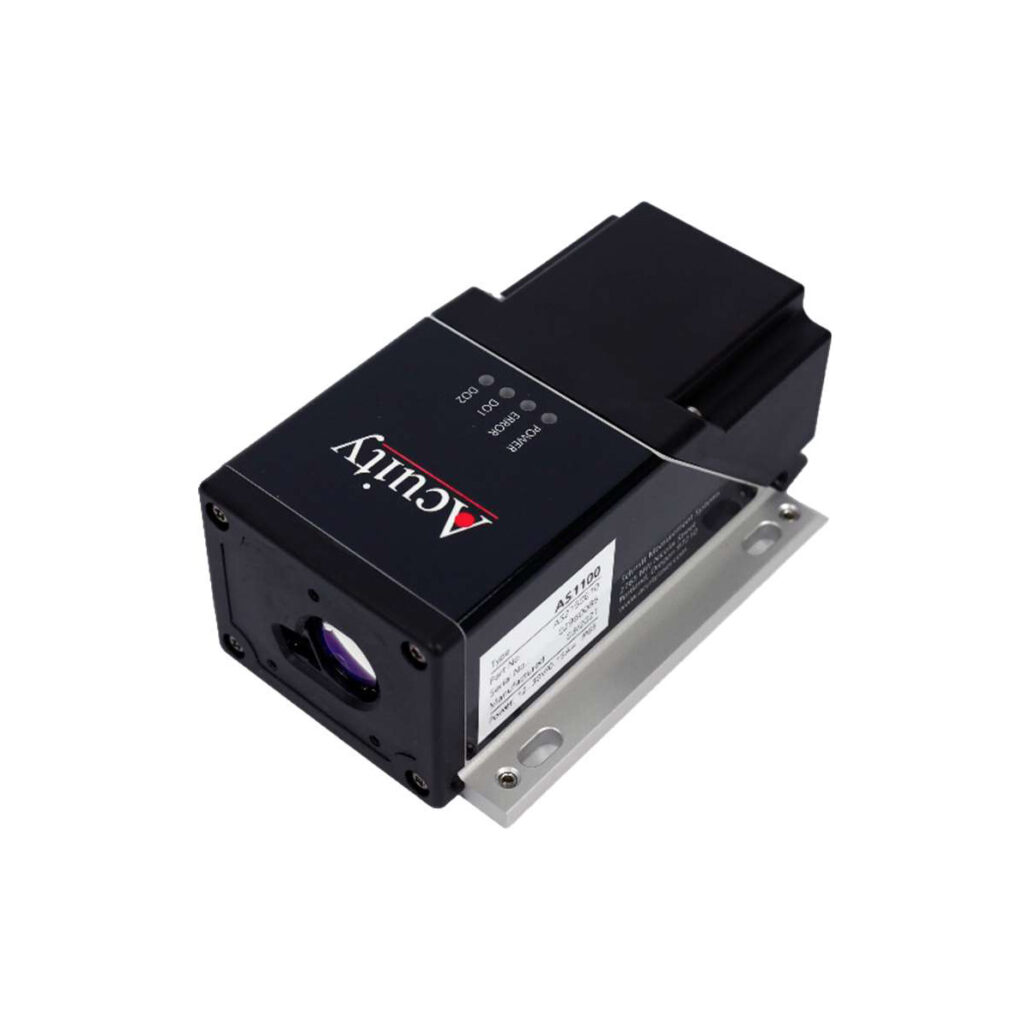

Steel, as well as iron, is used in the construction of roads, railways, appliances and in the structure of buildings. Due to the high demand for steelmaking, advanced technology is needed. At Acuity Laser, we highly recommend the use of the AS2100 series of laser sensors.

The AS2100 Accurate Distance Sensor is one of the best distance measurement sensors that function on hot surfaces or in bright lights. When steel products are being made, they must be heated to high temperatures in order to soften the alloy metals. In addition, a lot of steel work is done in bright lights, whether sunlight or in construction sites. For these reasons, as well as the high accuracy of the AS2100, many steel manufacturers will find that this line of lasers is the best choice. Many of our customers in steel manufacturing are using laser sensors in the production, processing, conveyance and storage of metallic materials. Non-contact thickness measurement can provide real-time measurements during high-speed production of steel plates and sheets.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.