Static and Dynamic Displacement Testing of Aircraft Structures Posted in: Displacement Measurement – Tags: Aerospace and Defense

Last Updated: March 20, 2023

To determine the strength of aircraft structures, components are mounted on tensile testing machines and loads are applied to measure the amount of forces aircraft structures are able to withstand. This is done in order to verify design loads and specifications of the aircraft. Typically, the displacement of these structures under load were measured with dial indicators, but often the parts under test, break off or come apart during the tests and damage the precision dial indicators.

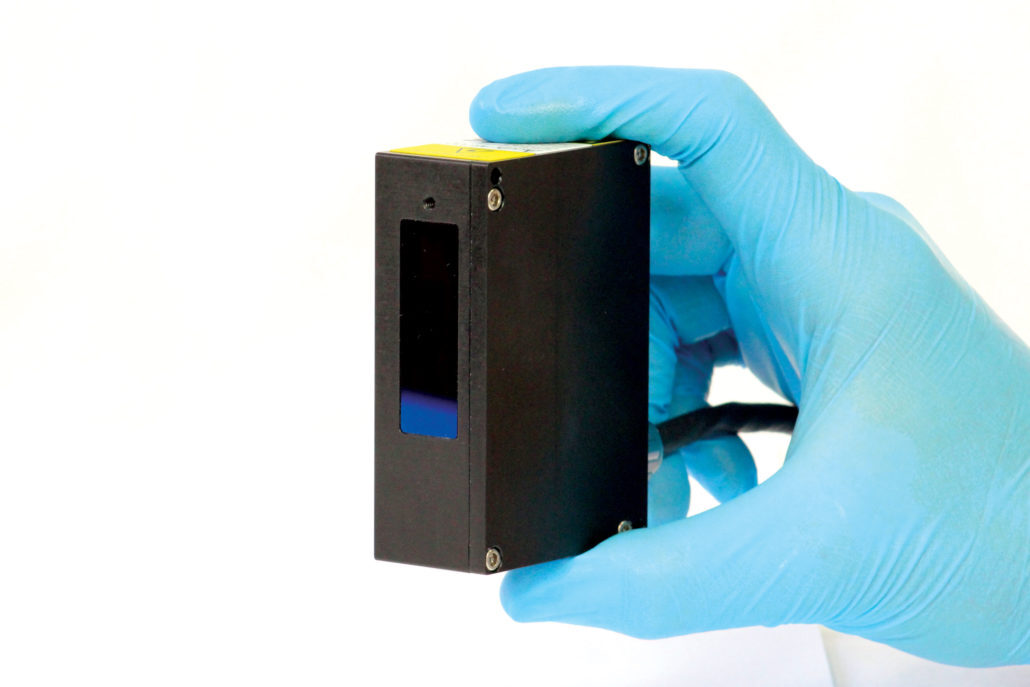

In support of this application, Acuity developed the AR700-2LR that provides a 2″ measurement range from a standoff of over 6″ with a linear accuracy of .0006″. The Acuity AR700-2LR laser displacement sensor has been demonstrated to have sufficient stand off as well as required accuracy to make these highly precise displacement measurements without being damaged during part failure. The AR700-2LR model has been proven to be very useful for carbon fiber components with long range displacements and deflections.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.