Rubber Thickness Measurement Posted in: Thickness Measurement – Tags: Tire and Rubber Manufacturing

Last Updated: March 20, 2023

Rubber Sheet Thickness Measuring with Laser Sensors

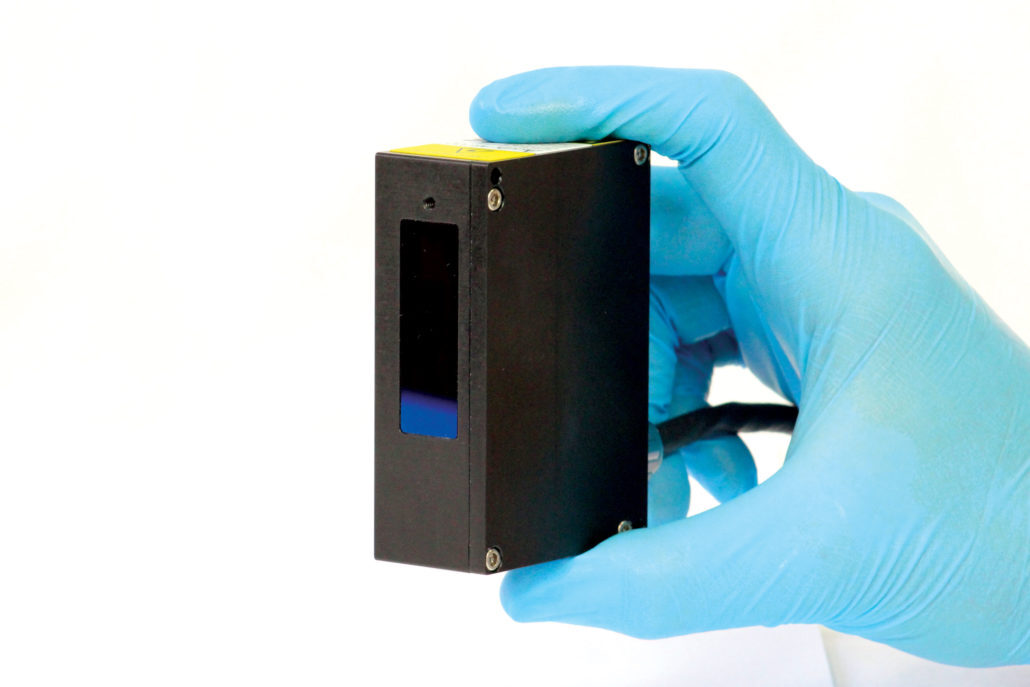

During calendaring and rubber processing, the surface of the rubber sheet is very shiny and very black, creating conditions where little light can be reflected. These are often the most challenging conditions for optical measurement sensors attempting to gauge rubber thickness measurement. Acuity can install an AR700 laser displacement sensor, bringing 5 mW of laser power to get a stronger return signal off the dark surface.

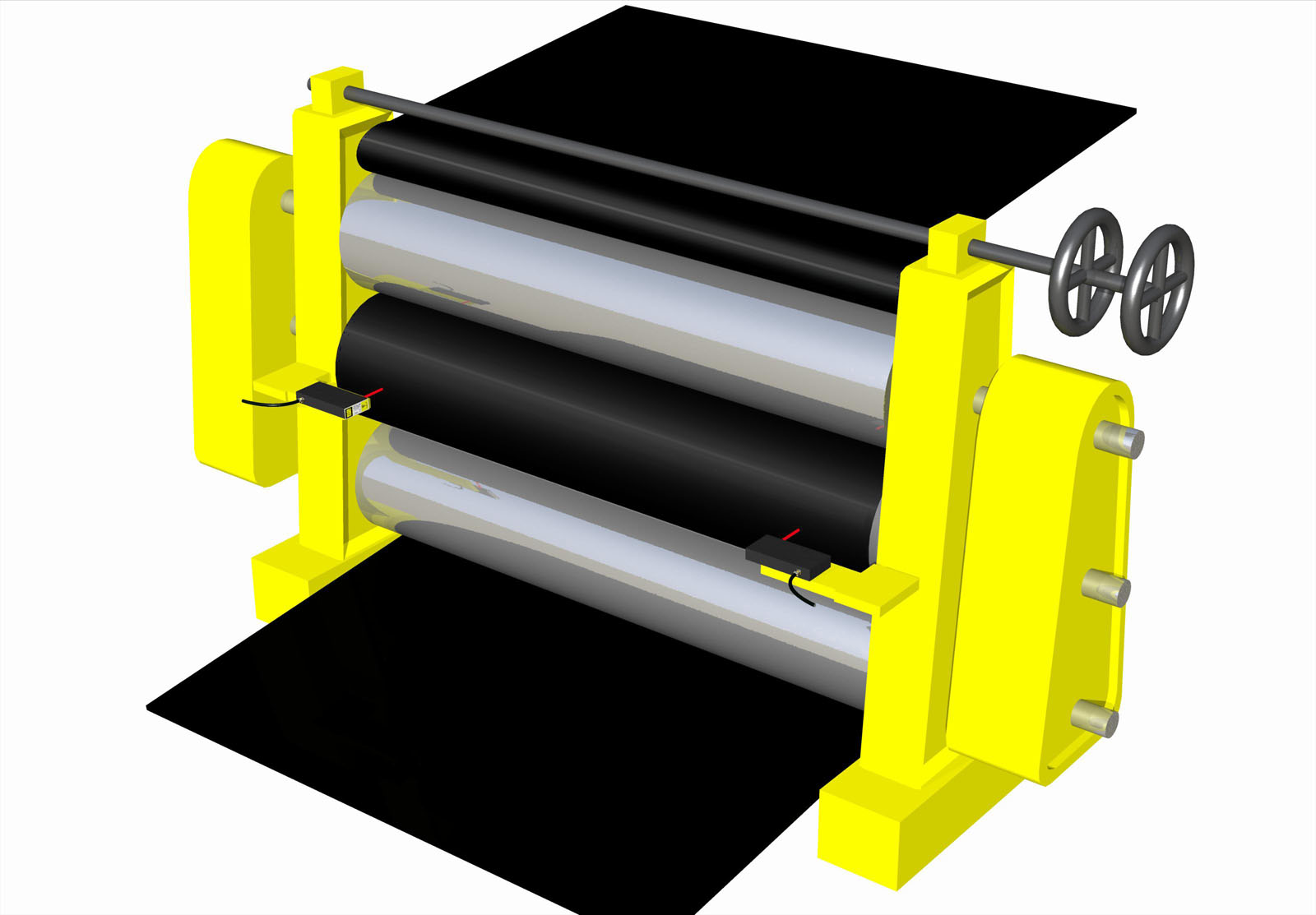

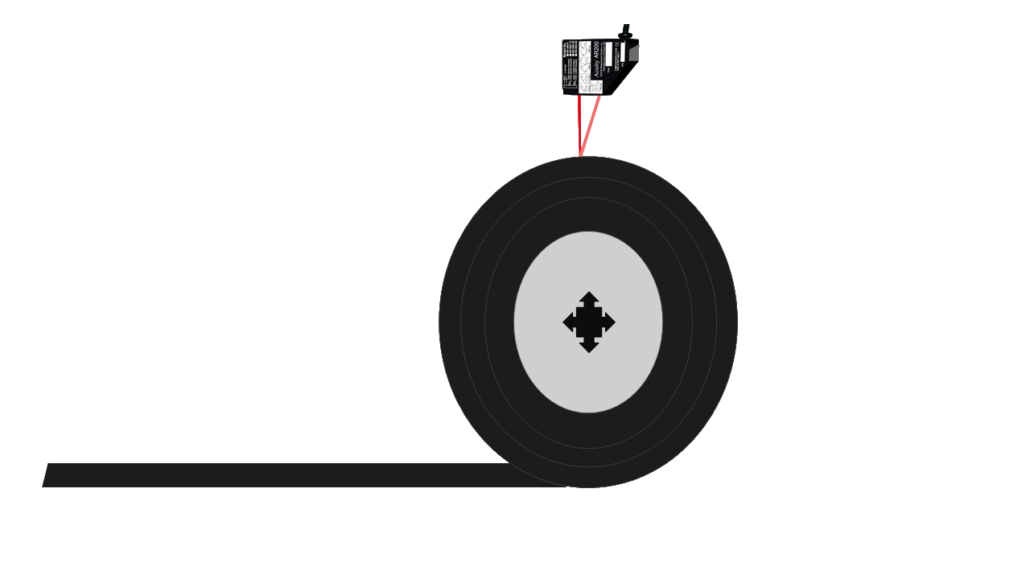

In one common scenario, a rubber manufacturer monitors their thickness measurements using four displacement sensors positioned at the top, 140 mm (5.5 in.) from the sheet surface. The rubber sheet lays across a roll cylinder. The top of the roller is the reference (zero) surface for thickness measurements. The laser spots aim directly perpendicular to the sheet surface at four different points across the sheet width for this process where the material stretches between two rollers, so that the roller gap can be adjusted accordingly to produce the desired (consistent) sheet thickness.

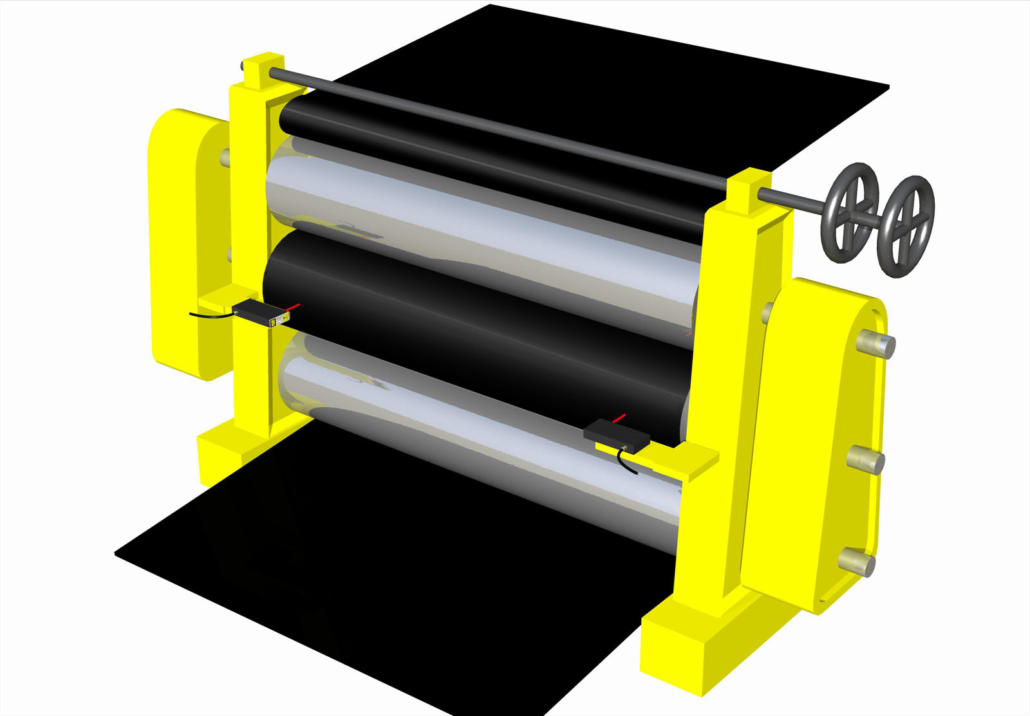

Customer installation for rubber thickness measurement:

Precise Laser Measurements

Acuity laser sensors are used widely throughout the rubber manufacturing industry. Manufacturers demand our reliable, non-contact sensors to minimize downtime and scrap material production.

Advantages include:

Online laser measurements for sheet thickness quality control

Reduce scrap material production

Excellent measurement of very shiny and very black rubber.

Related Products

Image Gallery

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.