Hot Steel Slab Width Posted in: Width Measurement – Tags: Metal and Steel Production

Last Updated: March 20, 2023

Hot Steel Slab Width Measurement with Laser Sensors

Non-Contact, Dimensional Measuring of Continuously-Casted Steel Using Lasers

Laser sensors are commonly used in steel hot mills because they need an accurate, non-contact method of determining the position or dimensions of materials that are too hot to touch. Many of Acuity’s customers are OEM integrators who service the specialized needs of the Steel and Aluminum Mill customers. They understand the challenges of using precision metrology equipment in hot mill environments. Mills may be very cold when not operative and extremely hot while steel is produced.

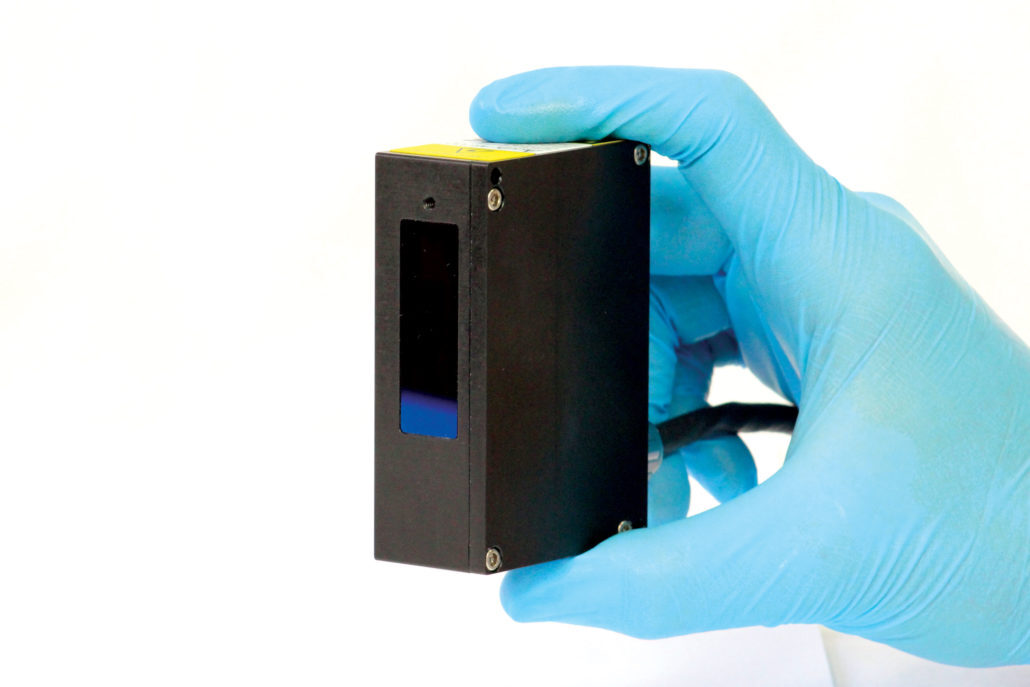

These machine builders use dual AR700-50 laser triangulation sensors in their width measurement systems that they install in worldwide steel mills. The application uses these sensors equipped with 20 mW infrared laser diodes to ensure a strong return signal off dark (cooled) or bright radiating steel (hot). The sensors are configured with narrow bandpass filters to eliminate the effects of emissive radiation from hot steel.

The sensors are installed in special, rugged enclosures that protect them from intense heat and potentially dirty environments. The housing is primarily water-cooled and forced air is used at the location of the laser sensor’s windows. The housed sensors are fixtured to heavy-duty floor-mounted poles. The sensors are aligned to each other, straddling the slab caster or roller table at the entry or exit to the reheat furnace. As the slab passes between the two sensors, the device measures the distance to the edges and calculates the material width.

This width measurement solution has been implemented throughout the United States, Canada, China, Germany, and other countries. For more information, please contact Acuity and we will be glad to refer you to one of several integrators who can implement a slab-width system in your mill.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.